Product

WELLGREEN SERIES

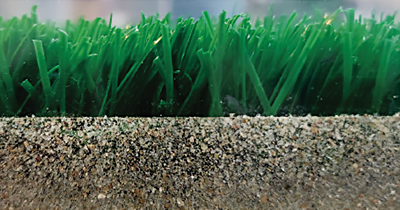

Artificial turf system reinforced with carbon nanotubes

It contains CNTs (carbon nanotubes) to increase properties of artificial turf systems, which are optimized for durability and setting the climate for all seasons.

Wellgreen 55

| Identification Number | 24224185 |

|---|---|

| Purpose | Soccer Field, Baseball Field, School Playground, etc |

| File Height | 55mm |

| File Material | PE + CNT |

| File Type | Monofilament |

| Structure | Single structure |

| Back Coating | SBR latex coating |

| Filling Material | DG CNT INFILL(Thermosetting Resin) + Silica sand |

| Color | Dark Green/Green |

Wellgreen 35 CNT

| Identification Number | 24865451 |

|---|---|

| Purpose | Futsal court, Foot volleyball court, Multipurpose stadium, etc |

| File Height | 35mm |

| File Material | PE + CNT |

| File Type | Monofilament |

| Structure | Single structure |

| Back Coating | SBR latex coating |

| Filling Material | DG CNT INFILL(Thermosetting Resin) + Silica sand |

| Color | Dark Green/Light Green |

Wellgreen 20 CNT

| Identification Number | 24865455 |

|---|---|

| Purpose | Tennis court, Lawn ball court, Park golf course, etc |

| File Height | 20mm |

| File Material | PE + CNT |

| File Type | Monofilament |

| Structure | Single structure |

| Back Coating | SBR latex coating |

| Filling Material | DG CNT INFILL(Thermosetting Resin) + Silica sand |

| Color | Dark Green/Green/Red Brown, etc |

Artificial Turf Yarn

(Patent Registration Number : 10-2046629)

-

The use of high-and-high polymer composite materials in the patented technology of artificial turf yarn

Daegun CNL Co., Ltd.'s artificial turf yarn is a product that improves the original properties of polyethylene (PE) by completely dispersing carbon nanotubes (CNTs), a polymer material, and mixing them with a plasma-treated master batch.

-

Enhancements through property value enhancements (PE)

In terms of durability, the purpose of this product is to prevent loss of fillers and maintain system performance by strengthening the overall function of the tensile strength and the elongation of the inverse value of the artificial turf yarn.

- It contains CNT (carbon nanotube) to improve the original physical properties and functions of the structure such as tensile strength and elongation to suit Korea's climate conditions, securing durability and reducing static electricity.

Artificial Turf Infill

(Patent Registration Number : 10-2283573)

-

Enhancement of functionality by improving attribute values (RUBBER)

It is manufactured with CNT to enhance the wear resistance and permanent compression rate of this synthetic rubber, and the filler is manufactured with thermosetting resin (within MAX: 200°C) so that it is not applied to a surface temperature of 70°C or higher.

-

Effect of reducing surface temperature through hydrophilicity

Hydrophilic performance is given according to the structural characteristics of our products, which reduces the surface temperature, allowing users to create a pleasant economy and reduce abrasions caused by burns and surface friction.

- CNT (carbon nanotube) reduces maintenance costs due to increased filler durability such as permanent compression ratio, and provides better wear resistance to prevent loss of silica sand and damage to yarn after installation of the structure. Furthermore, the hydrophilicity of the filler is excellent for reducing the surface temperature even in hot weather.

System Features

Even if the four seasons change

The original performance of the system such as tensile strength, elongation, and permanent compression ratio is strengthened and maintained for a long period of time by combining polymer materials rather than functional additives that cannot be fused or degrade performance.

The raw materials are honest and appropriate

Direct manufacture of infill with non-thermoplastic resin such as SEBS, PVB, TPE, etc., no thermal deformation or melting such as EP,BR, etc., and no damage to the system.

Direct production, delivery and management

From artificial turf mats to infill, which are components of the system, the company directly manufactures them for easy maintenance, and implements eco-friendly and product standardization, such as strengthening harmful substance quality standards.